High-Integrity Aluminum Castings. Fully Integrated. Uncompromisingly Precise.

As a proud member of the Ligon Permanent Mold Group, Watry Industries is one of the most advanced permanent mold aluminum foundries in the United States – recognized for its automation, process control, and total manufacturing integration.

Located in Sheboygan, Wisconsin, Watry delivers high-integrity aluminum castings and fully machined assemblies to OEMs and Tier 1 manufacturers across industrial, commercial vehicle, and power generation markets.

By combining engineering collaboration, robotic automation, and complete in-house finishing, Watry provides end-to-end control that ensures every component meets or exceeds performance expectations.

For more than 60 years, Watry has built its reputation on one principle: consistency through precision.

Advanced Permanent Mold Casting

Watry Industries specializes in permanent mold aluminum castings that achieve superior metallurgical integrity, dimensional accuracy, and repeatability.

Through process discipline and innovation, the company produces complex castings that deliver strength, durability, and performance under demanding conditions.

Core Casting Capabilities Include:

- Reverse-Tilt Pouring: Controlled metal flow minimizes turbulence and improves casting quality.

- Robotic Pouring and Extraction: Automation ensures repeatable results and tight process control.

- Semi-Permanent Mold Casting: Integration of sand cores for intricate internal cavities.

- Automated Mold Preparation and Cooling: Real-time control of mold temperatures for consistent results.

- High-Integrity Alloys: Engineered for strength, ductility, and corrosion resistance.

Each casting reflects Watry’s meticulous process control – from alloy melt to final inspection – delivering performance and quality that customers can trust.

Total In-House Integration

Watry’s strength lies in its vertical integration.

Unlike traditional foundries that rely on multiple subcontractors, Watry manages the entire production process internally, providing speed, flexibility, and accountability at every step.

In-House Capabilities:

- Casting & Core Making: Precision permanent mold and semi-permanent mold processes.

- CNC Machining: Multi-axis machining centers capable of complex geometries and tight tolerances.

- Powder Coating & Surface Finishing: Durable finishes with uniform appearance and corrosion protection.

- Assembly & Testing: Complete mechanical assembly, leak and pressure testing, and dimensional validation.

- Quality Assurance: ISO-certified inspection and traceability from raw material to final shipment.

This seamless integration enables Watry to deliver shorter lead times, consistent quality, and single-source responsibility for even the most complex programs.

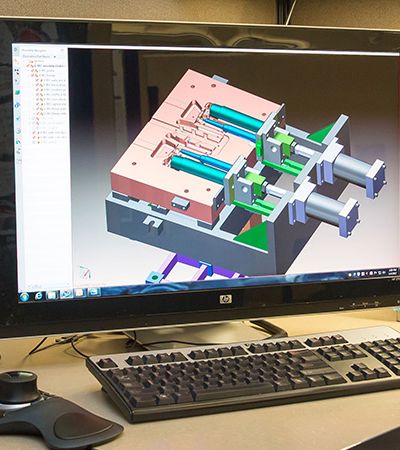

Engineering Collaboration

Watry’s process begins with partnership.

Its engineers collaborate with customer design teams early in the development cycle to identify opportunities for optimization, cost reduction, and performance improvement.

By aligning engineering intent with manufacturing capability, Watry ensures every design translates smoothly into production.

Engineering Services Include:

- Design-for-manufacturability (DFM) and design-for-casting (DFC) reviews

- 3D modeling and simulation of fill and solidification

- Alloy selection and mechanical property consultation

- Prototype casting and validation testing

- Continuous improvement through feedback and analysis

This engineering collaboration reduces risk, accelerates development, and ensures that each casting performs flawlessly in its final application.

Industries Served

Watry Industries serves a diverse mix of customers who require high-integrity aluminum components for mission-critical applications.

Its combination of engineering expertise and manufacturing control has made it a trusted supplier across multiple industrial sectors.

Primary Industries Include:

- Industrial Equipment: Precision castings for pumps, compressors, and enclosures.

- Commercial Vehicles: Lightweight structural components engineered for strength and durability.

- Power Generation: Complex castings built to perform in high-stress thermal environments.

- Fluid & Air Handling: Leak-free castings designed for flow control and pressure systems.

- Construction & Agricultural Equipment: Reliable aluminum components that withstand heavy duty use.

Across all these industries, Watry’s commitment to quality and responsiveness helps customers meet production goals with confidence.

Quality Systems & Certifications

Watry’s pursuit of excellence is driven by an ISO 9001:2015 certified quality management system and a company-wide culture of continuous improvement.

Every casting undergoes rigorous testing, inspection, and documentation to ensure absolute conformance.

Quality Highlights:

⦁ ISO 9001:2015 certification

⦁ Non-destructive testing (NDT) including X-ray and dye-penetrant inspection

⦁ Leak and pressure decay testing for fluid applications

⦁ Metallurgical and dimensional analysis using CMM technology

⦁ Statistical process control (SPC) and traceability reporting

By maintaining these disciplined quality standards, Watry guarantees not only exceptional performance but also the reliability customers expect from an industry leader.

Automation and Process Innovation

Watry Industries continues to push the boundaries of permanent mold technology through ongoing investment in automation, robotics, and digital process monitoring.

These innovations drive efficiency, reduce variability, and ensure every casting meets the exact same standards – batch after batch.

Automation Advantages:

⦁ Robotic pouring, extraction, and mold handling

⦁ Automated mold preheat and temperature control

⦁ Data-driven process monitoring and adaptive control

⦁ Real-time quality tracking and feedback systems

⦁ Reduced human variation, improved safety, and faster cycle times

This continuous pursuit of process innovation ensures Watry remains at the forefront of modern aluminum casting technology.

Part of the Ligon Permanent Mold Group

As a key member of the Ligon Permanent Mold Group (LPMG), Watry Industries contributes its automation expertise and integrated production model to a national network of aluminum foundries.

Together with Alcast Company, Premier Aluminum, and Stahl Specialty Company, Watry expands the group’s capacity, flexibility, and collective engineering knowledge.

Group-Wide Benefits Include:

⦁ Shared engineering resources and best practices

⦁ Scalable capacity across multiple U.S. foundries

⦁ Unified quality management and certification standards

⦁ Cross-industry insight and innovation

⦁ Streamlined RFQ and program management support

Through this collaboration, customers gain the efficiency of a large manufacturing network combined with the precision and accountability of a specialized foundry partner.

Why Partner with Watry Industries

⦁ Complete Vertical Integration: Casting, machining, finishing, and assembly all under one roof.

⦁ Engineering Partnership: Collaborative design and problem-solving from prototype through production.

⦁ Automation Leadership: Robotic systems that enhance consistency and reduce lead time.

⦁ Quality Assurance: ISO-certified systems and full traceability for every component.

⦁ Group Strength: Backed by the resources and reliability of the Ligon Permanent Mold Group.

When precision, reliability, and scalability are mission-critical, Watry Industries delivers the confidence manufacturers depend on.

Request an Engineering Consultation

Work directly with Watry’s engineering and production teams to explore how advanced permanent mold casting can optimize your product design, improve quality, and streamline manufacturing.

Submit an RFQ or request an engineering consultation today to experience the performance of true process integration.