Engineering Strength. Foundry Excellence. Unified Innovation.

Ligon Permanent Mold Group (LPMG) is a vertically integrated family of aluminum foundries united by one goal: to engineer and deliver world-class permanent mold castings that meet the most demanding performance, quality, and delivery standards. With four highly respected foundries – Alcast Company, Premier Aluminum, Stahl Specialty Company, and Watry Industries – LPMG provides unmatched versatility, capacity, and technical depth across the aluminum casting industry.

Each foundry operates with its own proven specialties and strengths, while collectively offering the power of shared engineering expertise, advanced manufacturing technologies, and group-wide quality standards. Together, we help OEMs and Tier 1 suppliers streamline sourcing, reduce lead times, and achieve production confidence from prototype to full-scale manufacturing.

When precision, reliability, and collaboration matter most, manufacturers turn to the Ligon Permanent Mold Group.

A Vertically Integrated Network of Aluminum Foundries

Under the Ligon Permanent Mold Group, customers gain access to four specialized foundries – each known for its excellence in a specific niche of the aluminum casting industry. Whether the requirement is for complex, large-scale structural castings or rapid-turnaround prototypes, LPMG’s unified network ensures a solution built on precision, innovation, and trust.

Our Group Capabilities Include:

- Permanent mold, semi-permanent mold, tilt pour, and reverse-tilt pour casting

- Complete in-house CNC machining, heat treatment, and finishing

- Powder coating, impregnation, and assembly operations

- Non-destructive testing, leak and pressure decay testing, and X-ray inspection

- Engineering consultation and rapid prototyping

- ISO 9001:2015 and ITAR-certified facilities

LPMG’s collective infrastructure gives customers a single source for aluminum casting solutions – offering scale, flexibility, and speed that few independent foundries can match.

Our Foundries

Alcast Company – Precision Permanent Mold Expertise

Alcast Company, based in Peoria, Illinois, is recognized nationwide for precision permanent mold castings with exceptional consistency and strength. The company’s proprietary Mitchener Molding Process virtually eliminates porosity while delivering superior dimensional accuracy.

With in-house heat treating, CNC machining, and powder coating, Alcast provides turnkey solutions from prototype to production. Serving industries such as Defense, Heavy Equipment, Powertrain, and Marine, Alcast embodies engineering-driven performance trusted by some of the world’s most demanding manufacturers.

Premier Aluminum – Prototype to Production with Speed and Flexibility

Located in Racine, Wisconsin, Premier Aluminum specializes in low- to medium-volume aluminum castings and is built around an agile, engineer-to-engineer partnership model. Known for rapid prototyping, flexible tooling, and short lead times, Premier serves industries requiring adaptability without sacrificing quality or precision.

From permanent and tilt-pour casting to full CNC machining, helium testing, and finishing, Premier helps manufacturers move from concept to component faster – backed by the reliability of LPMG’s shared engineering resources and ISO 9001:2015 standards.

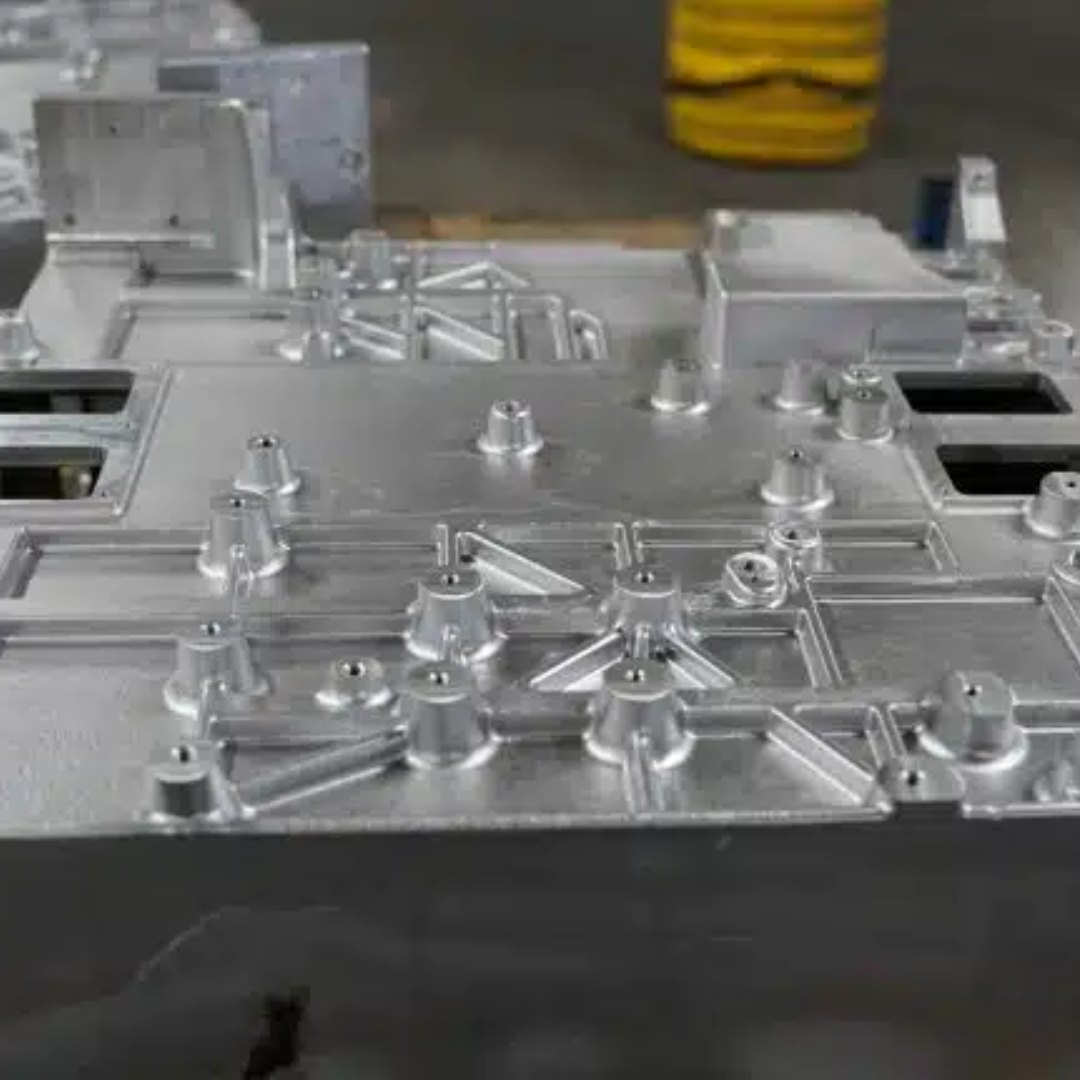

Stahl Specialty Company – High-Volume, High-Performance Casting

With facilities in Kingsville and Warrensburg, Missouri, Stahl Specialty Company is one of the largest permanent mold foundries in North America. Stahl’s expertise lies in large, complex castings and high-volume production supported by advanced automation, robotics, and continuous process control.

The company serves automotive, defense, and heavy equipment industries, providing aluminum components weighing from just a few pounds to over 400 pounds. Stahl’s comprehensive capabilities – core making, machining, and heat treatment – deliver precision at scale.

Watry Industries – Fully Integrated Casting, Machining, and Assembly

Based in Sheboygan, Wisconsin, Watry Industries delivers high-integrity permanent mold aluminum castings for industrial, commercial vehicle, and power generation applications.

Watry combines robotic pouring and extraction systems, reverse-tilt processes, and full in-house machining, assembly, and testing to deliver precision parts with exceptional reliability.

From design collaboration to turnkey manufacturing, Watry’s process integration embodies the LPMG commitment to quality, efficiency, and partnership.

Unified Engineering Expertise

What truly distinguishes Ligon Permanent Mold Group is the depth of collaboration between its foundries. By sharing engineering knowledge, process improvements, and materials science insights, LPMG empowers each location to perform at the highest level while ensuring consistent results across all facilities.

When customers engage with any LPMG foundry, they gain:

- Access to collective engineering knowledge from hundreds of experts

- Scalability from small-batch prototyping to full production programs

- Multi-industry experience with a focus on long-term reliability

- Proven processes that reduce lead times and minimize production risks

This synergy transforms traditional vendor relationships into strategic partnerships – helping customers bring stronger, lighter, and more reliable aluminum components to market faster.

Why Partner with Ligon Permanent Mold Group

- Comprehensive Capabilities: From complex prototypes to high-volume castings, LPMG provides the right process for every requirement.

- Engineering Collaboration: Our group’s shared technical expertise ensures design optimization and manufacturability.

- Quality Assurance: ISO 9001:2015 certification and rigorous testing deliver consistent quality and performance.

- Speed & Flexibility: Vertically integrated processes reduce time-to-market and improve supply chain reliability.

- National Scale, Local Precision: With multiple U.S. facilities, LPMG offers both regional support and national reach.

Through vertical integration, shared innovation, and a dedication to partnership, Ligon Permanent Mold Group stands as a leader among U.S.-based aluminum foundry networks.

Request an Engineering Consultation

Whether you’re developing a new component or seeking to optimize an existing design, Ligon Permanent Mold Group connects you to the right foundry expertise for your project.

Submit an RFQ or request an engineering consultation today to discover how our unified network can deliver the precision, performance, and partnership your program demands.